Deck Crane Servicing

Our Deck Crane Servicing ensures the smooth operation and safety of your crane system.We conduct regular inspections, lubrication, and adjustments to maintain optimal performance.Thorough examination of crane components such as cables, hooks, and controls to identify any wear or damage.

Inspection of hydraulic components for leaks, pressure checks, and fluid level management.

Verification of safety features like limit switches, emergency stops, and overload protection systems.

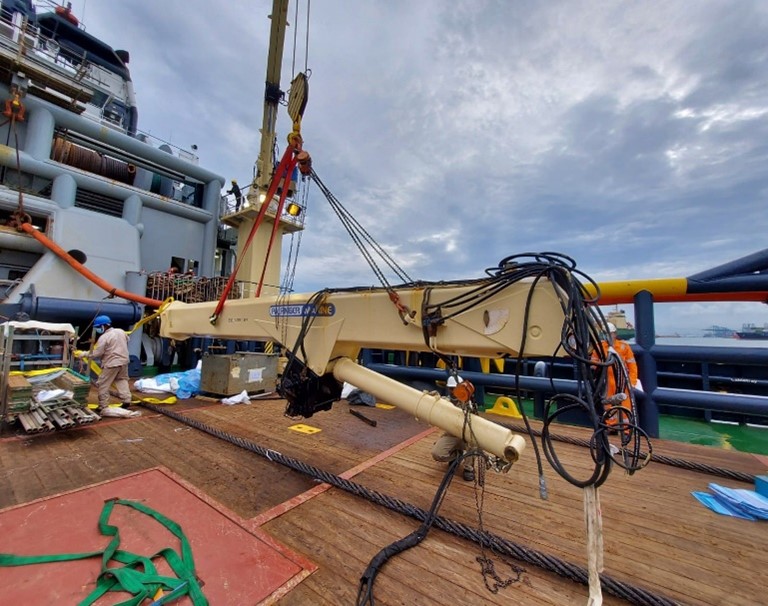

Cargo Crane Boom Repair

Our Cargo Crane Boom Repair service focuses on restoring functionality and safety

- Boom Inspection: Comprehensive inspection of the crane boom for structural integrity, weld quality, and corrosion

- Welding and Fabrication: Expert welding techniques and custom fabrication for repairing damaged boom sections

- Alignment and Calibration: Alignment checks and calibration to ensure the boom operates within specified parameters

- Load Testing: Rigorous load testing after repairs to verify structural strength and stability

- Painting and Corrosion Protection: Application of protective coatings and corrosion prevention measures for long-term durability

New Anchor Replacement

Our New Anchor Replacement service ensures secure anchoring and marine safety

- Anchor Selection: Assistance in selecting the right anchor type and size based on vessel specifications and operating conditions

- Installation Planning: Detailed planning and preparation for anchor installation, including positioning and securing

- Anchoring Equipment: Supply of high-quality anchors, chains, shackles, and accessories for a complete anchoring system

- Installation and Testing: Professional installation of anchors followed by thorough testing to ensure proper function and security

- Documentation and Compliance: Documentation of anchor replacement procedures and compliance with maritime regulations and standards

Bow Thruster Service

Our Bow Thruster Service enhances maneuverability and control of your vessel

- Thrust Assessment: Evaluation of thrust performance to determine efficiency and effectiveness

- Cleaning and Inspection: Thorough cleaning and inspection of thruster components for debris, corrosion, and wear

- Seal Checks: Examination of seals and bearings for leaks and proper lubrication

- Alignment and Adjustment: Alignment checks and adjustments to optimize thrust direction and balance

- Maintenance Recommendations: Recommendations for ongoing maintenance practices to prolong thruster lifespan and efficiency

Engine Reduction Gearbox Servicing

Our Engine Reduction Gearbox Servicing maximizes engine efficiency and longevity

- Gearbox Inspection: Detailed inspection of gearbox components for wear, alignment, and lubrication

- Fluid Analysis: Analysis of gearbox oil for contaminants, viscosity, and lubricating properties

- Seal and Gasket Checks: Examination of seals and gaskets for leaks and proper sealing

- Gear Meshing Checks: Verification of gear meshing for proper engagement and minimal wear

- Performance Testing: Testing of gearbox performance under load conditions to ensure optimal functionality

Anchor Windlass Break Cylinder Servicing

Our Anchor Windlass Break Cylinder Servicing ensures reliable anchoring operations

- Break Cylinder Inspection: Thorough inspection of break cylinders for leaks, wear, and hydraulic pressure

- Hydraulic System Checks: Examination of hydraulic components, hoses, and connections for integrity and functionality

- Cylinder Maintenance: Cleaning, lubrication, and adjustment of break cylinders for smooth operation and braking efficiency

- Functional Testing: Testing of break cylinders under load conditions to verify braking performance

- Safety Compliance: Adherence to safety regulations and standards for break cylinder servicing and maintenance

Lifeboat Hydraulic Cylinder Servicing

Our Lifeboat Hydraulic Cylinder Servicing ensures the reliability and safety of lifeboat systems

- Cylinder Inspection: Thorough inspection of hydraulic cylinders for leaks, corrosion, and proper functioning

- Seal Checks: Examination of seals and gaskets for wear and leaks, with replacements as needed

- Pressure Testing: Testing of hydraulic pressure systems to ensure safe and efficient operation

- Lubrication and Adjustment: Lubrication of moving parts and adjustment of hydraulic settings for optimal performance

- Emergency Response: Readiness for emergency repairs and maintenance to keep lifeboat systems operational at all times

- Certification Compliance: Adherence to certification requirements and safety standards for lifeboat hydraulic systems

Crane Swing Motor Servicing

Our Crane Swing Motor Servicing enhances the reliability and functionality of crane swing operations

- Motor Inspection: Detailed inspection of crane swing motors for wear, alignment, and electrical connections.

- Electrical Testing: Testing of motor electrical components, wiring, and controls for proper function and safety

- Lubrication and Greasing: Lubrication of motor bearings and gears for smooth and efficient operation

- Alignment and Calibration: Alignment checks and calibration of motor settings for accurate swing motion

- Load Testing: Testing of swing motor performance under load conditions to ensure reliability and stability

- Preventive Maintenance: Recommendations for ongoing preventive maintenance to extend motor lifespan and performance